Membran-tech (MF)

Membran-tech (MF) is a Microfiltration plant which is used in the dairy industry for bacteria reduction from skim milk and whey, cheese brine clarification and protein fractionation in cheese milk.

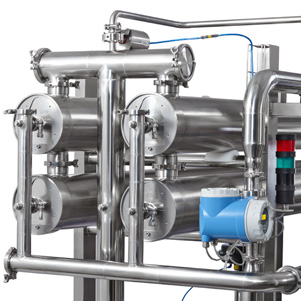

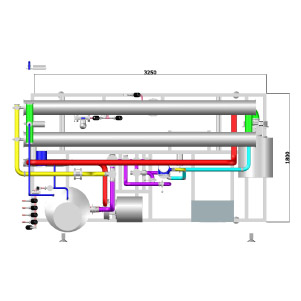

Membran-tech (MF) systems are fully self-contained and skid-mounted, providing our customers with several benefits such as space saving, short installation time, easy maintenance and membrane replacement. The units are fully automated, available in various sizes/capacities. The units are fully tested prior to delivery and come fully cabled ready for production.

APPLICATIONS OF MICROFILTRATION IN THE DAIRY INDUSTRY

Bacteria and spore removal from skim-milk, for improved and premium quality ESL milk.

The process of microfiltration removes bacteria and spores from milk and therefore it is essential for the production of Extended Shelf Life (ESL) milk.

In this process, Raw milk is preheated and separated with the resulting skim milk then being microfiltered into the Membran-tech plant.

In the Membran-tech plant the skim-milk is separated into two fractions: Permeate ( low bacterial content) and retentate (high bacterial Content).

The retentate is removed separately for further processing (it is considered a secondary product), while pasteurized cream is introduced to the permeate. The mix is then homogenized, pasteurized and packaged. The product can have up to a 40 day shelf life when stored below 4°C.

Bacteria and spore removal from skim-milk, for additive free cheese making.

In this process the retentate is not removed separately but it is mixed with a standard quantity of cream. The mix is then sterilized by high heat and reintroduced to the permeate. The blended milk is further processed in the downstream equipment.

Casein Fractionation.

In the protein fractionation processes using membranes with 0.1 to 0.5 micron pore size in the Membran-tech plant, large proteins (casein micelles) are separated from the small soluble proteins (whey proteins). This application produces a casein-rich milk concentrate that can be used for cheese making and a fat free serum milk protein stream that can be further processed with Ultrafiltration to make a Whey protein-type concentrate.

Cheese Brine Clarification.

Cheese brine may often contain large yeast and mould counts, whose content can be reduced with processing it in the Membran-tech plant. With the microfiltration method the chemical composition of the brine is not changing as this happen during pasteurization.

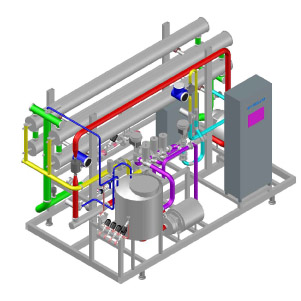

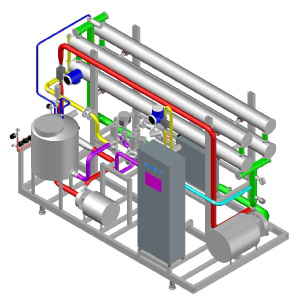

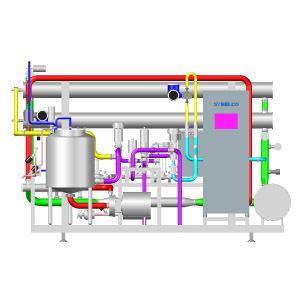

All the processing plants are designed in 3-D before their construction, giving to our customers the possibility of selecting the most ergonomic solution.

In proportion with the needs of each customer Membran-tech systems can basically be divided into 4 main categories:

Products and Services

Processing Units

Latest News

Certification ISO 9001:2015

Official partners of ALFA LAVAL