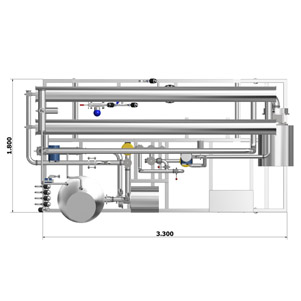

MEMBRAN-TECH (UF) – MILK / WHEY

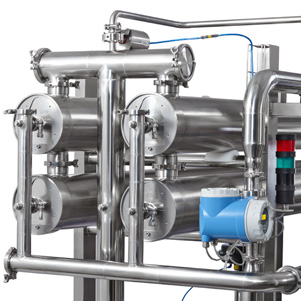

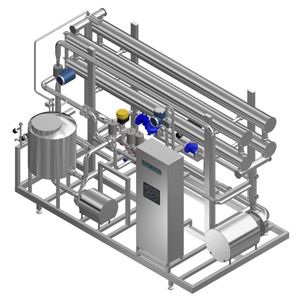

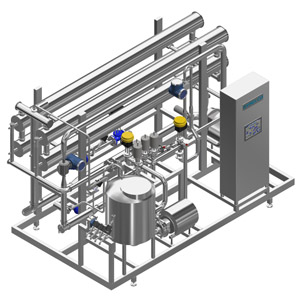

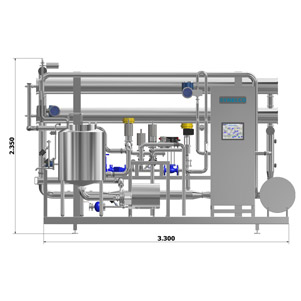

Membran-tech (UF) systems are fully self-contained and skid-mounted, providing our customers with several benefits such as space saving, short installation time, easy maintenance and membrane replacement.

The units are fully automated, available in various sizes/capacities.

The units are fully tested prior to delivery and come fully cabled ready for production.

SYNELCO offers a pilot plant unit for product testing and process development at your plant site.

BENEFITS AND ADVANTAGES OF ULTRAFILTRATION IN THE DAIRY INDUSTRY

UF technology is used for production of white cheeses, whey cheeses and Greek style yogurt.

Benefits of protein standardization in cheese making:

Benefits of protein concentration in whey:

Advantages of Ultrafiltration:

All the processing plants are designed in 3-D before their construction, giving to our customers the possibility of selecting the most ergonomic solution.

In proportion with the needs of each customer Membran-tech systems can basically be divided into 4 main categories:

Products and Services

Processing Units

Latest News

Certification ISO 9001:2015

Official partners of ALFA LAVAL